Picking the right loader for a compact tractor is probably the single biggest decision you can make to boost productivity on your farm or smallholding. Get it right, and you turn hours of back-breaking manual work into a quick, easy job. Your tractor suddenly becomes a do-it-all machine.

How to Choose the Right Loader for Your Compact Tractor

Choosing the perfect loader isn’t just about how much it can lift; it’s a serious investment in how your whole operation runs. The right model completely changes your daily routine, whether you’re mucking out stables, moving bales, doing a bit of landscaping, or clearing overgrown land. There’s no single ‘best’ loader – the right one is the one that fits your setup.

To get it right, you need to have a good, honest look at three things: your tractor’s power, the jobs you’ll be doing most often, and the ground you’ll be working on. Nail this assessment from the start, and you’ll end up with a loader that serves you well for years to come.

Matching the Loader to Your Operation

The classic mistake is buying a loader that’s either too big or too small for the tractor. A loader that’s too heavy puts a massive strain on the tractor’s chassis and hydraulics, which can lead to costly damage and is a real safety hazard. On the flip side, an underpowered loader will just struggle with every task, slowing you down and never quite getting the job done properly.

A correctly specified loader doesn’t just lift materials; it elevates your entire operation’s efficiency. It becomes a natural extension of your tractor, working in harmony with its capabilities rather than against them.

It’s no secret that the market for compact tractors and their attachments is booming. This reflects just how much we’ve come to rely on them, especially in livestock farming where a good loader is indispensable for handling feed and materials. Here in the UK, the compact tractor market is definitely growing, and it’s the less-than-40 HP segment – the sweet spot for these loaders – that’s expanding fastest.

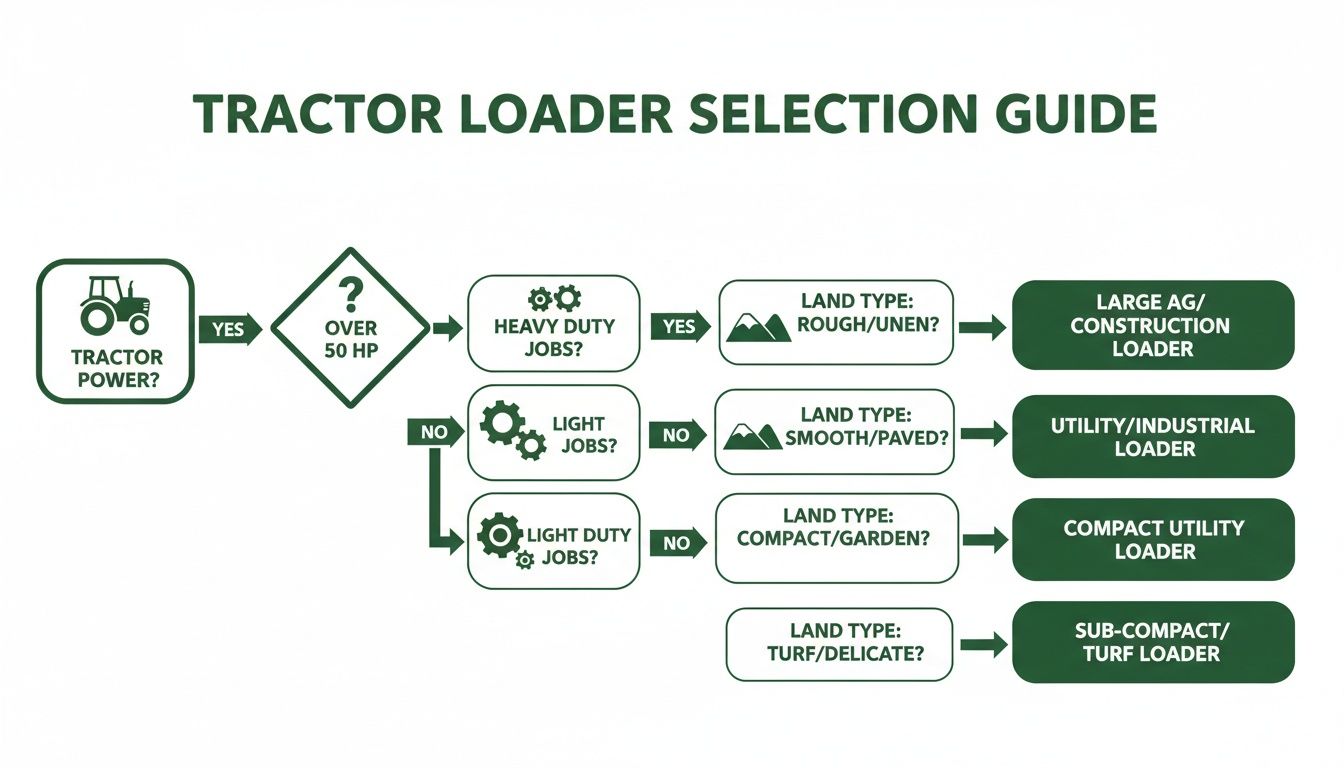

This simple chart helps to visualise the thought process, taking you from your tractor’s horsepower to the jobs and terrain you’re dealing with.

As you can see, each step – power, jobs, and land type – helps you zero in on the loader that’s a perfect match for what you need.

Getting to Grips with Loader Specs and What They Really Mean

Staring at a spec sheet for a front end loader can feel a bit like reading a foreign language. All those numbers and technical terms are there for a reason, but they only become useful once you know how they translate to your daily work on the farm or smallholding. Let’s break down the figures that truly matter.

These numbers aren’t just for show; they directly impact how effectively and safely you can get your jobs done. Nailing this part is the key to choosing a loader that works with your tractor, not against it.

Lift Capacity: What You Can Actually Shift

Lift capacity is the headline figure everyone looks at first, and rightly so. It tells you the maximum weight the loader can lift. But there’s a catch. This rating is almost always measured right at the pivot pins—the point where the loader arms join the bucket. The further the load is from those pins, the less you can safely lift.

It’s better to think about it in practical terms:

- Feed and Supplies: Will it lift a full pallet of feed bags or fertiliser without grumbling? A decent loader for a 30 HP tractor should manage around 500-700 kg, which covers most daily jobs.

- Bale Handling: If you’re running livestock, can it handle your bales? A big round bale of silage can easily top 600 kg, so you’ll need a loader with enough grunt to match.

For instance, a loader rated for 500 kg at the pins might only handle 350 kg safely on a set of pallet forks because the weight is now sitting much further forward. Always look for both figures if the manufacturer provides them.

Lift Height: Reaching New Levels

This one’s simple: how high can the loader lift its bucket or attachment? This becomes vital when you’re stacking materials high to save space or loading into tall-sided trailers and muck spreaders—a common task on UK farms.

Picture this: you’re trying to stack hay bales in the barn to see you through the winter. A loader without enough lift height will force you to make a wide, low stack, eating up precious covered storage. Likewise, if your trailer sides are high, you need a loader that can clear them easily without spilling half your load on the floor. For most compact tractors, a lift height around 2 to 2.5 metres (roughly 6.5 to 8 feet) is a good benchmark.

A loader’s true value isn’t just in lifting heavy loads, but in its ability to place those loads exactly where they need to go, safely and efficiently. The right combination of lift capacity and height saves time and your back.

Breakout Force: The Real Muscle

Breakout force might be the most underrated spec, but it’s where the real work gets done. It’s the raw power the loader can exert to “break” a load free from a pile. This is the force that pries packed manure from the ground or digs into a stubborn pile of gravel.

A loader with a high lift capacity but poor breakout force might be able to lift a heavy bucket of loose soil, but it will struggle to even fill that bucket from a compacted heap. This is where you can tell a well-engineered loader from a cheap one. It’ll have the hydraulic power to curl the bucket with immense force, making tough digging jobs a whole lot easier.

Weight and Balance: The Stability Factor

Finally, we need to talk about the loader’s own weight. It’s a delicate balancing act. A loader needs to be tough enough for hard graft, but not so heavy that it overloads the tractor’s front axle and makes it unstable. An oversized loader makes a tractor dangerously front-heavy, especially on the kind of uneven ground you find all over the British countryside.

This is why a proper counterweight on the back of the tractor is absolutely non-negotiable. A correctly matched loader and tractor, balanced with enough rear weight, keeps all four wheels firmly on the ground. This isn’t just about safety; it protects your tractor’s chassis and front axle from unnecessary stress, giving your whole investment a much longer life.

A Closer Look at Loader Types and Mounting Systems

When you’re in the market for a loader, it’s easy to get focused on pure lifting power, but that’s only half the story. Not all loaders for compact tractors are created equal, and how they actually bolt onto your machine is just as crucial as what they can lift. This connection point dictates the real-world versatility and day-to-day efficiency of your entire setup.

For most folks on UK farms and smallholdings, the go-to choice is the classic Front-End Loader (FEL). It’s the undisputed workhorse, designed for a massive range of jobs, from mucking out to moving pallets. But the real magic happens at the end of the loader arms, where your attachments connect. Understanding the mounting system here is what truly unlocks your tractor’s potential.

Quick-Attach vs. Pin-On Systems

You’ll mainly come across two types of mounting systems: Quick-Attach (often called QA) and the more traditional Pin-On. The difference between them is night and day.

Think of a Quick-Attach system like a modern cordless drill. You can snap a drill bit out and pop in a screwdriver head in seconds. That’s exactly what QA does for your loader. It’s a universal coupling that lets you drop a bucket and hook up to pallet forks or a grapple in under a minute, often without even getting out of the driver’s seat.

A Pin-On system, on the other hand, is a more old-school, permanent-feeling connection. Each attachment is fixed directly to the loader arms with two chunky pins. Swapping attachments means knocking out those pins (usually with a hefty hammer), lining up the new tool, and hammering the pins back in. It creates a rock-solid, rigid link, but it’s a slow, manual job.

If you’re tackling several different jobs in a day, a Quick-Attach system isn’t just a nice-to-have; it’s practically essential. It transforms your tractor from a one-trick pony into a genuine multi-tasking machine, saving you a huge amount of time and effort.

This need for versatility is a big driver on modern UK farms. Compact tractors are right at the heart of this, especially in the under-40 HP segment, which is seeing the fastest growth. This part of the UK’s agricultural tractor market, valued at £445 million in 2023, is expected to climb to £668 million by 2030. That growth is fuelled by farmers needing one machine that can do it all. You can discover more insights about UK agricultural tractor market growth on Grandviewresearch.com.

Why a Sub-Frame Mount is Non-Negotiable

While the attachment system is about speed and flexibility, the way the whole loader rig connects to the tractor itself is all about strength and protecting your investment. This is where the sub-frame mount really shines.

A proper sub-frame is a purpose-built steel cradle that bolts to the front of the tractor, runs back underneath the engine, and secures to the strongest parts of the main chassis, usually near the rear axle. It’s a brilliantly simple piece of engineering.

By doing this, it spreads the huge stress of lifting heavy loads across the entire length of the tractor’s frame. Instead of all that force being focused on the front axle and engine block, it’s shared out, which prevents metal fatigue and provides a far more stable, planted feel when you’re working.

The alternative is a cheaper ‘direct-to-frame’ mount that just bolts to the side of the engine. While it might seem fine for very light duties, it puts all that strain on a small, vulnerable area. Over time, with heavy, repetitive work, that can lead to a cracked chassis—a catastrophic and costly failure. For any serious agricultural use, a full sub-frame isn’t an option; it’s the only sensible choice to protect your tractor for the long haul.

Essential Attachments to Maximise Your Loader

A loader on its own is a fantastic bit of kit, but its true power is only really unleashed when you start pairing it with the right attachments. Think of it this way: the standard bucket is your starting point, but the real jump in productivity comes from tools built for specific jobs around your farm or smallholding. Moving beyond the basics is what transforms your compact tractor into a true multi-purpose workhorse, ready to tackle dozens of different tasks.

This is where you start solving those everyday problems and genuinely boost your efficiency. With the correct attachment, a job that once chewed up half your day could be done and dusted in minutes.

Beyond the Bucket: The Most Useful Tools

Let’s look at the attachments that really deliver the goods for UK operators, turning your loader for a compact tractor into a far more versatile machine. These tools are all about tackling the common challenges we face on British farms.

- Pallet Forks: Honestly, these are probably the second most important attachment you’ll own after a bucket. They make moving seed pallets, fertiliser bags, and IBCs of liquid feed a simple, safe, one-person job. No more wrestling with heavy sacks or waiting around for a second pair of hands.

- Grapple Bucket: A grapple bucket is an absolute game-changer for clearing overgrown land, managing woodland, or just tidying up. It can securely grip awkward loads like logs, brush, and rocks, making site clean-up faster and a whole lot safer than trying to balance everything precariously in a standard bucket.

- Bale Spear (or Spike): For anyone with livestock, a bale spear is a must-have. It simplifies feeding routines massively, letting you move and place round or square bales with pinpoint accuracy, whether you’re dropping them into a feeder or stacking them high in the barn.

Just these three attachments alone can completely change the way you work, saving you countless hours of back-breaking manual labour over the course of a year.

Specialised Attachments for Targeted Gains

Once you’ve got the basics covered, you can look at specialised attachments designed to solve very specific problems. These tools often provide a direct and measurable return on your investment because they’re engineered to fix a particular inefficiency.

Take feed waste, for example—it’s a significant hidden cost on many farms. Every scrap of silage left stuck to the silo wall or dropped during transit is money down the drain. This is where a purpose-built tool really shines.

A specialised attachment is designed to do one job exceptionally well. While you might not use it every single day, its impact on efficiency and cost-saving for that specific task can be huge, often paying for itself surprisingly quickly.

A fantastic example of this in action is the JF Hudson Silo Crab. This attachment is engineered specifically to get at the leftover silage that a standard bucket just can’t reach. It cleanly scrapes the silo face and recovers material that would otherwise be wasted. For a livestock farmer, that directly reduces feed costs and boosts the bottom line.

Choosing the Right Tool for Your Operation

The key to choosing the right attachments is to honestly look at your most time-consuming or wasteful tasks and find the tool designed to solve that exact problem. A well-chosen attachment doesn’t just make the work easier; it makes your entire operation more profitable.

Here’s a quick rundown of some popular attachments and where they fit best.

Common Loader Attachments and Their Primary Uses

| Attachment | Primary Use on a UK Farm | Best Suited For | JF Hudson Solution (if applicable) |

|---|---|---|---|

| Standard Bucket | Moving loose material like soil, gravel, muck, and grain. | General-purpose loading, grading, and carrying. The go-to for most daily tasks. | N/A (Standard with most loaders) |

| Pallet Forks | Lifting and transporting palletised goods, IBCs, and fence posts. | Farms handling bagged feed/seed, logistics, and material handling. | Yes – Custom forks available. |

| Grapple Bucket | Clearing brush, logs, rocks, and other bulky or irregular items. | Land management, forestry work, and clearing overgrown areas. | Yes – Custom grapples available. |

| Bale Spear | Moving and stacking round or square bales of hay, silage, or straw. | Livestock farms, equestrian centres, and hay producers. | Yes – Custom bale spikes. |

| Silo Crab | Scraping and recovering leftover feed from silo walls to reduce waste. | Dairy and livestock farms looking to maximise feed efficiency. | Yes – The JF Hudson Silo Crab. |

Ultimately, thinking about your machine as a complete system is the key to unlocking its full potential. To get the most from your loader, you also have to consider how you balance the tractor. For instance, a sturdy front weight can double as handy storage. You can find out more by exploring the benefits of a compact front box for both ballast and secure tool carrying. It all works together.

Getting Set Up: Safe Installation and Operation

So, you’ve picked out the perfect loader. Brilliant. But the job’s not done yet. Getting it fitted correctly and knowing how to run it safely is the next, and arguably most important, step. This isn’t just about ticking boxes on a checklist; it’s about protecting yourself, your tractor, and anyone else on your land. A well-matched, properly installed loader is a dream to operate, but get it wrong, and it can be a real hazard.

Putting in the effort now to get these fundamentals right will pay you back every single time you use it, both in how well it performs and in your own peace of mind.

The Pre-Installation Compatibility Checklist

Before you even think about reaching for a spanner, you need to be 100% sure your new loader and compact tractor are a good match on paper. It’s about more than just seeing if the brackets line up; you need to dig into the technical specs.

The heart of the operation is your tractor’s hydraulic system. You need to know two key numbers:

- Hydraulic Flow Rate (LPM): This is measured in litres per minute and basically controls how fast your loader moves. If the loader needs more flow than your tractor can provide, you’ll be left with frustratingly slow performance.

- System Pressure (Bar): This is the muscle, the force that gets the work done. The loader has to be rated to handle your tractor’s pressure, or you risk blowing seals and hoses.

Just as critical is the tractor’s own structure. You absolutely must verify your tractor’s front axle capacity. Think about it – every kilo you lift is putting immense strain on that axle. Overloading it is a fast track to a very expensive, catastrophic failure. Always, always stay well within the manufacturer’s limits.

Counterweight: The Cornerstone of Safety

If there’s one thing to take away from this guide, it’s this: proper counterweight is non-negotiable. When you lift a heavy load in the bucket, you’re massively shifting the tractor’s centre of gravity forward. Without enough ballast hanging off the back, the rear wheels will lift, and that’s a terrifyingly easy way to tip the whole machine over, especially on a slope.

Never operate a loader without adequate rear counterweight. It is the single most effective way to maintain stability and prevent a potentially life-threatening rollover incident.

This is where smart, British-made kit really shines. A JF Hudson Weighted Front Box, for example, doesn’t just give you the essential ballast to keep your tractor firmly on the ground; it also provides secure, weatherproof storage for tools or supplies. It’s that kind of practical, dual-purpose thinking that comes from understanding what UK farmers actually need day-to-day. If you have a specific requirement, looking into customisation and precision engineering services can get you a solution that’s a perfect fit for your setup.

Your Daily Pre-Start Checks

Make a habit of a quick walk-around before you start work. It takes two minutes but could save you from an accident or a costly breakdown. This simple checklist should become second nature.

- Check for Leaks: Have a good look around the hydraulic hoses, connectors, and rams. A tiny drip can turn into a major failure once it’s under pressure.

- Inspect Pins and Bushings: Make sure all the locking pins are properly seated and give the joints a wobble to check for any excessive play or wear.

- Tyre Pressures: Check your tyres are at the correct pressure, especially the fronts. Your manual will tell you what they should be.

- Confirm Ballast: Give your counterweight a once-over to ensure it’s properly attached and secure.

- Clear the Area: Make sure there are no people, animals, or other obstacles anywhere near where you’ll be working.

Remember, a loader changes how your tractor feels and handles. Keep your loads low to the ground when travelling, take corners slowly, and be extra cautious on slopes. A high load makes a tractor top-heavy and dangerously unstable. Treat it with respect, and your loader will be a productive asset, not a liability.

Why British Manufacturing Delivers for UK Farmers

Choosing the right loader for your compact tractor is about more than just comparing spec sheets. It’s about finding a piece of kit that’s built for the reality of UK farming. When you opt for British-made machinery, you’re not just buying steel and hydraulics; you’re investing in engineering that’s been fine-tuned for our specific climate, our ground, and our way of working.

That local insight is what really makes the difference. British manufacturers don’t just design loaders; they design them to handle the damp, the mud, and the unpredictable conditions we all know too well. This means you get tougher, more durable equipment that’s built to survive a proper British winter, not just a sunny afternoon in California.

The Advantage of Local Expertise

There’s a massive benefit to having support right on your doorstep. When you need a spare part, a bit of advice, or a custom-made solution, dealing with a local manufacturer means you get a fast response from people who genuinely get what you’re up against. No more waiting weeks for a part to be shipped from halfway across the world or struggling to explain a problem over a language barrier.

British-made agricultural equipment is born from a direct dialogue with the farmers who use it. This feedback loop ensures that products aren’t just engineered in a lab—they’re proven in the field, solving real-world problems.

It’s precisely why our own products at JF Hudson, from the innovative Silo Crab to our customisable Front Boxes, exist. They are the direct result of listening to what farmers need. It’s our commitment to building things that actually work for you. You can learn more about our British manufacturing heritage and ethos on our website.

Custom Solutions for Unique Challenges

The market for compact loaders here in the UK is growing fast, which tells you just how vital this kind of versatile equipment has become for modern farming. Businesses that specialise in British-made attachments, like our Silo Crab, are perfectly placed to meet this demand with solutions that make a tangible difference—like cutting silo waste by up to 20-30%. If you’re interested in the numbers, you can discover more insights about the compact loader market on fortunebusinessinsights.com.

This local connection also unlocks some serious problem-solving power. An off-the-shelf product from a catalogue can’t always fix a unique challenge on your farm. That’s where precision engineering services come in. Whether you need a bespoke bracket for an older tractor or a modified attachment for a very specific job, the ability to design and create custom solutions is a real hallmark of British manufacturing. It’s about building a genuine partnership to find the right answer for the jobs you face every day.

Got Questions? We’ve Got Answers

Stepping into the world of loaders for compact tractors can throw up a few questions. We get it. To help you out, we’ve put together some of the most common queries we hear from UK farmers and operators, along with straightforward answers to guide your decisions.

How Much Can a Compact Tractor Loader Actually Lift?

This really depends on the specific tractor and loader you’re pairing up. For most compact tractors you see on UK farms, usually in that 25-50 HP sweet spot, you’re looking at a lift capacity anywhere from 350 kg to over 1,000 kg.

But here’s a crucial bit of real-world advice: that headline number is almost always measured right at the pivot pins. Once you stick a set of pallet forks on the front, your practical lifting power will be less because the weight is further out. Always dig into the loader’s specific ratings to stay safe.

Do I Really Need to Add Extra Weight to My Tractor?

Yes, one hundred per cent. A rear counterweight isn’t just a good idea—it’s vital for keeping the tractor stable and safe. When you lift a heavy bucket of soil or a pallet of feed, all that weight up front can make the tractor dangerously light at the back. It’s surprisingly easy to lift the rear wheels clear off the ground, creating a serious tipping risk, especially on bumpy terrain.

You’ve got a few solid options for ballast:

- Pop a heavy implement on the back, like a rotavator or a box blade.

- Fill the rear tyres with liquid ballast for a low-profile solution.

- Attach a purpose-built weight block directly to the tractor’s linkage.

A well-balanced tractor is a safe tractor. Never skip the counterweight. It’s the key to stable loader work and protects both you and your machine from harm.

What’s the Difference Between Quick-Attach and Pin-On?

This is all about how you swap your tools. A pin-on system is the old-school, traditional method where you physically pin the bucket or other attachment directly onto the loader arms. It’s a strong, simple connection, but changing implements is a manual job that takes time and effort.

On the other hand, a quick-attach system is a game-changer for versatility. It uses a universal mounting plate with simple levers, letting you switch from a bucket to forks to a grapple in just a couple of minutes, usually without needing any tools. If you’re constantly juggling different jobs, a quick-attach setup will save you a huge amount of time and hassle.

How Much Does Hydraulic Flow Matter for Loader Speed?

It matters a lot. Hydraulic flow, measured in litres per minute (LPM), is essentially the lifeblood of your loader—it dictates how fast everything moves. More flow means faster cycle times, which translates to quicker lifting, lowering, and tilting.

Most loaders are designed to work well with the hydraulic output of the tractors they’re built for, but it’s still a spec you need to double-check. A mismatch can leave you with a sluggish, frustratingly slow loader or, in some cases, could even strain your tractor’s hydraulic system.

Ready to fit your compact tractor with British-made attachments built for the realities of UK farming? Take a look at our range of durable, no-nonsense solutions at JF Hudson Ltd.

Visit jfhudson.co.uk to learn more and find the perfect fit for your operation